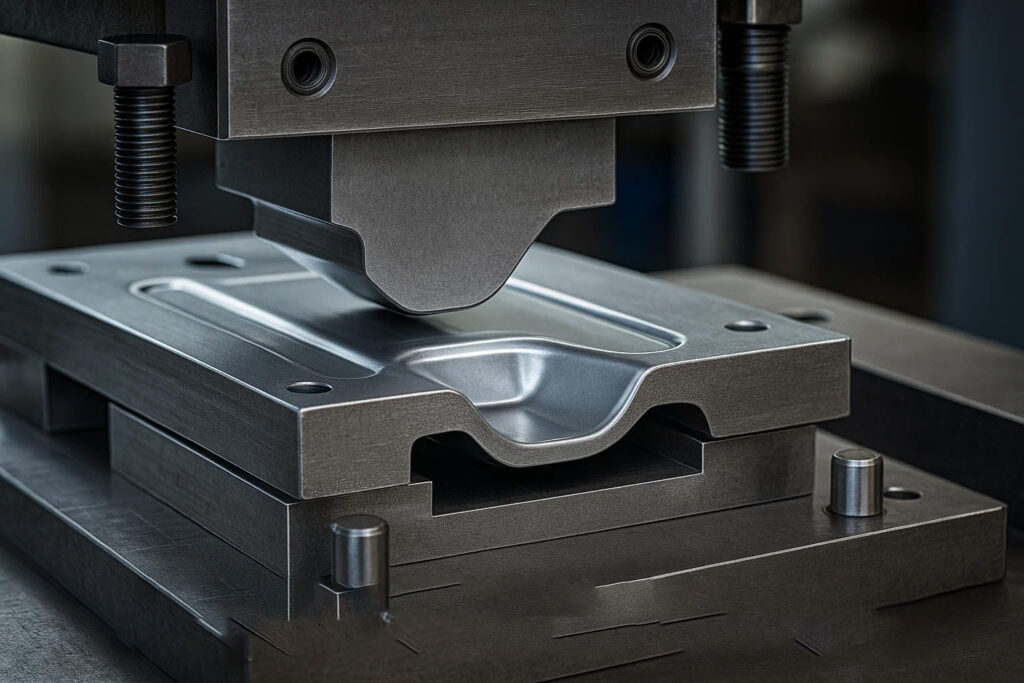

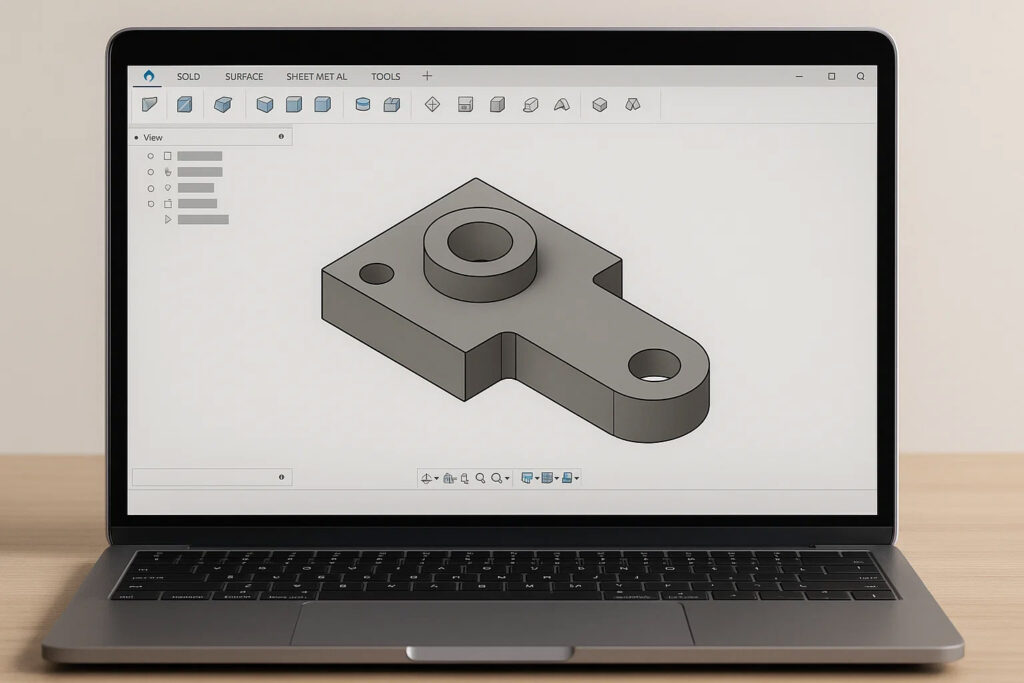

At ANA Global, we combine precision, scale, and innovation to deliver world-class manufacturing solutions for OEMs and regulated industries. With vertically integrated facilities in the United States and Mexico, we provide a seamless customer experience—design to delivery—backed by decades of expertise.